We often read headlines about microchip shortages, but don’t hear as much about the shortage of critical raw minerals. Today, on Global Recycling Day 2022, we shed some light on how Environmental Solutions Asia recycles waste material from chip makers (also known as semiconductor fabrication plants). To this end, we create a circular loop for Fluorspar which is a critical raw mineral for the steel-making industry.

From Waste Sludge…

Calcium Fluoride (CaF2) sludge is a common waste generated when manufacturing electronics, ranging from microchips to LED screens and even solar panels. In the case of microchip fabrication, the use of Hydrofluoric Acid in the etching process produces this waste sludge. During the process, the acid dissolves parts of the chip to carve out intricate patterns. At the end of it, fluoride-containing wastewater is produced. This is then precipitated with Calcium Hydroxide and Calcium Chloride — generating Calcium Fluoride sludge.

…to Critical Raw Mineral

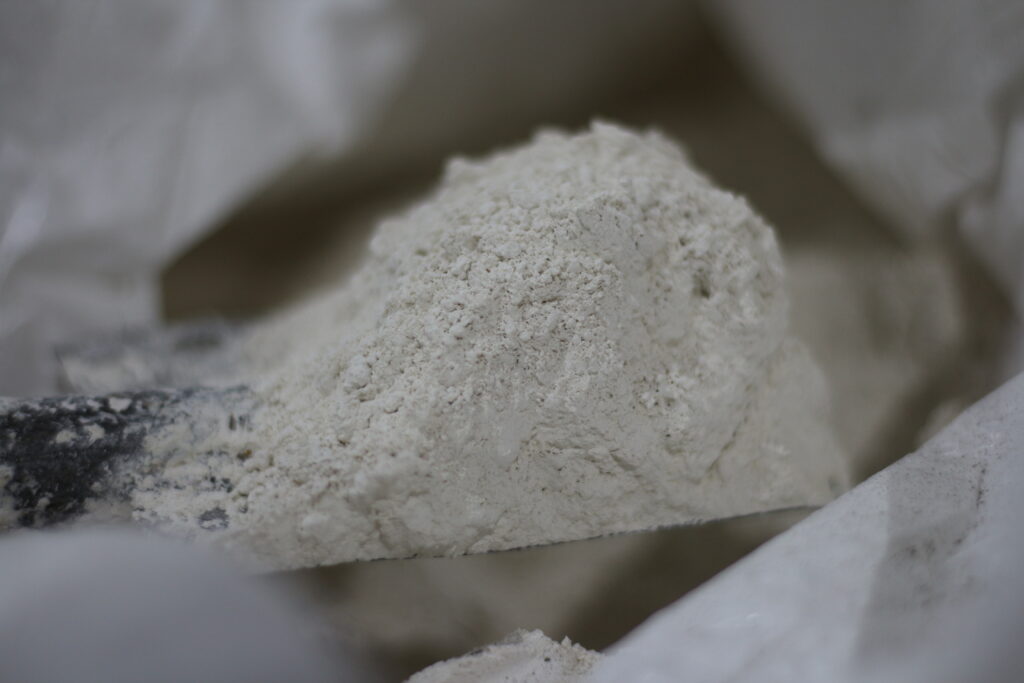

At ESA, we recycle this waste sludge in our thermal processing plant to create synthetic fluorite, also known as Fluorspar. Fluorspar is a naturally-occurring mineral with millions of uses. It is critical for the production of many things — from the simple non-stick cooking pan to the generation of clean, renewable energy, and even microchips. This raw mineral is needed to make Hydrofluoric Acid.

The recycled Fluorspar produced at ESA is of the metallurgical grade. We sell this mineral to companies that work with metals like steel or aluminium. For example, factories that manufacture aluminium electrodes or construction steel will require Fluorspar as a flux during the smelting stage. By using a flux, the smelting process can occur at a lower temperature and/or remove impurities.

Benefits of Recycling Calcium Fluoride Sludge

- Saving our Landfill: Since Calcium Fluoride sludge is a non-incinerable waste in Singapore, it would have been sent to our one and only landfill. Hence, by recycling these sludges, we are able to divert them away from the landfill and improve our client’s environmental scores.

- Reducing Risk of Pollution: More than 50% of the Fluorspar circulating in the world is mined from the grounds in China. However, by creating a synthetic substitute of this natural resource from waste, we are able to reintroduce these minerals back into the circular economy. This allows us to reduce the risk of pollution — both associated with the disposal of Calcium Fluoride sludge waste as well as the mining of virgin Fluorspar.

- Reducing Carbon Emissions using Renewable Energy: Plus, our use of renewable energy in our operations would reduce comparable carbon emissions by approximately 36%. This is because we opt to gasify waste wood to power our process rather than using diesel or other fossil fuels to do so.

If you are looking to sustainably manage Calcium Fluoride sludges or other industrial waste, get in touch. Alternatively, if you are sourcing for sustainable Fluorspar, email us at CaF2@env-solutions.com.